BFM2000 E:

The BFM 2000 E is an electric mixing container with a hook arm sled that can be pulled by a truck, making it easily transportable. The sloping bottom allows the pump to suction more bentonite solution from the tank. It also features an elevated hopper table that is accessible via a fixed ladder. Placing the hopper table above the pumps keeps the mixing container compact and provides the drilling supervisor with a clear view of both the mixing container tank and the surroundings. For ease of use, the stainless steel control cabinet has additional buttons near the hopper table, allowing the drilling supervisor to control the mixing container from the platform.

This mixing container comes with two big bag frames, which can be placed on top of the hopper table so that the crane can perform other tasks. It also has a special Bofram venturi, various connections including a recycle mud connection, and a float level measurement.

Extra options:

- 2 x steel frame for big bag suspension on top of the hopper table

- Extra transfer pump 37 KW incl. Control and motor switches

- Remote control with pneumatic valve (faster reaction time), on pre-pressure pipe

- Bottom frame hook system permanent or with twist locks

- Big bag frame 2 x for above hopper table, incl. Permanent set-up option. Frame height to wishes of the customer.

- Signal tower for level measurement tank

- Special impeller in mix pump for faster maturation Bentonite (shear effect)

- Valve control with signal from the drill

Mixing unit BFM 2000 E

| Frame | Steel container with sloping bottom (for easier cleaning) |

| Dimensions | 7000 (L (mm)) X 2440 (W (mm)) x 2500 (H (mm)) |

| Power drive | Electric |

| Mix pump | MCM mix pump with ceramic seal 5x6x14 ” with 55 KW electric motor equipped with a special impeller for faster ripening of Bentonite |

| Mix capacity | 2000 liters per minute |

| Transfer pump | MCM transfer pump 5x6x13″ suitable for 1500 ltr/min flow with 2,5 bar, 37 KW |

Specifications mixing unit:

- Lowered drain point

- Lowered suction point for pumps

- Convex side walls (light in weight), open version

- Stairs: 1 x external (fixed staircase) and 1 x internal in tank

- 2 x mixing pipe PE version with 2 x 8 pcs Eductors, for fast riping Bentonite

- Various connections to customer’s wishes

- Hopper table suitable for BigBag use

- Special venturi for fast intake of Bentonite powder

- Float type level measurement, the pointer on the side of the container, 2-sided

- Recycle mud connection according to customer’s requirements

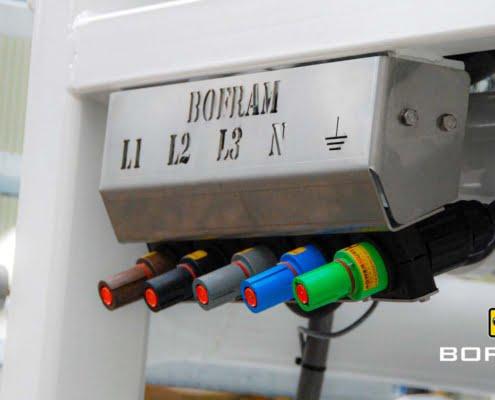

- Stainless steel control box (at hopper table)

- Conservation: blasted primer and 2K topcoat (inside and outside) or scooping and lacquering

- Piping carried out in PE where possible

- Worklights: 1 x set up at hopper table 1 x at mix pump

- Steel coarse water filter, easy to clean

- Valve control via remote control