Horizontal Directional Drilling – How does it work?

Step 1: Pilot drilling

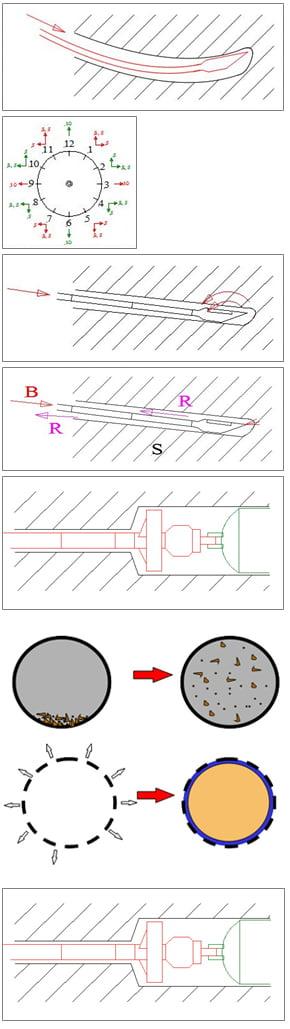

Making the pilot bore is by far the most important step, as this phase determines the final route of the pipeline. In the pilot borehole, a drillhead with a jet is positioned at the end of the flushing tubes. A “steering plate” is positioned on the drill head. By rotating the steering plate, the drillhead will move in different directions. Turning the steering plate in a certain direction causes the drill head to follow.

Figure 1 on the right illustrates how the steering plate (at an angle to the drillhead) steers the drillhead upwards.

By rotating the rods 90° to the left, right or 180°, the drillhead can be steered “unrestrictedly”. In this way, certain obstacles can be avoided. The position of the drill head is shown on a “clock”, which is visible to the driller via the measuring system.

By allowing the rods to rotate continuously, the drillhead will simply go straight ahead and not change direction.

When drilling the pilot hole, it is important that there is sufficient bentonite, so that you get a nice borehole and the following steps are easier to carry out.

B= Drilling fluid S=Round R=Returning fluid (= B+S)

The figure on the right shows how the jet at the front of the drill head loosens the sand and, by means of the drilling fluid, drives the sand out of the hole.

Step 2: Clearing the borehole

After the pilot drilling, a reamer is used to enlarge the borehole so that the tube to be installed can be pulled out.

During the final reaming stage, the pipe is attached to the reamer by means of a swivel and is pulled into the borehole. The purpose of the swivel is to prevent the tube from rotating.

During the reaming it is important to respect the calculated reaming time, which is calculated on the basis of the quantity of soil to be transported and the capacity of the pump that pumps the bentonite. If the reaming is done too quickly, sand deposits may occur because the speed of the reaming mixture becomes lower than the speed required to transport the sand. The drilling fluid to be used is Quik-gel or Wyoming bentonite. This form of bentonite has proven its worth over many years. It is a type of bentonite that is easily mixed with water, resulting in a smooth drilling fluid that works well in different types of soil.

The drilling fluid has 5 different functions:

- Transporting the loosened soil

- Keeping the loosened soil “in solution

- Maintaining the stability of the borehole by laying a film

- Lubricating

- Cooling down the parts

Step 3: Positioning the pipe

As mentioned earlier, during the final stage of reaming the pipe is attached to the reamer by means of a swivel and is thus pulled into the borehole.

In order to reduce friction as much as possible, the pipe is temporarily placed on supports (rollers). The distance between the rolls depends on the type of material (PE, steel, …), the diameter and the thickness of the pipe.

Bofram is specialized in Bentonite pump units for horizontal directional drilling

The mix pump units developed and built by Bofram are 100% remote-controlled. The liters, working pressure, and engine speed can be read on the remote control.

The machines we develop are super-advanced tools for HDD activities with many advantages; fuel savings, time savings, easy error detection. Additionally, we offer service and maintenance to all the HDD equipment we deliver.

If you have any questions or comments regarding this article, please feel free to contact us. We are happy to help you.

Advice or questions about directional drilling?

Call for an appointment +31 (0)486-459045 or mail to info@bofram.nl