“One in three streets in the Netherlands has to be torn up” or not?

A little while ago, we saw in the NOS news that by 2050, one in three streets will have to be torn up or demolished in order to lay new green electricity cables. This is because the current electricity cables are too light for the amount of energy we require from them. The demand for electricity will only grow in the future. It has become increasingly popular to install an electric heat pump or to drive an electric car. All for the sake of the climate. In order to facilitate this sustainable energy, a total of 60,000 to 80,000 kilometers of new cable is needed underground. That are quite a lot of streets and quite a lot of inhabitants of the Netherlands who will experience temporary inconvenience. Or will it?

Horizontal directional drilling

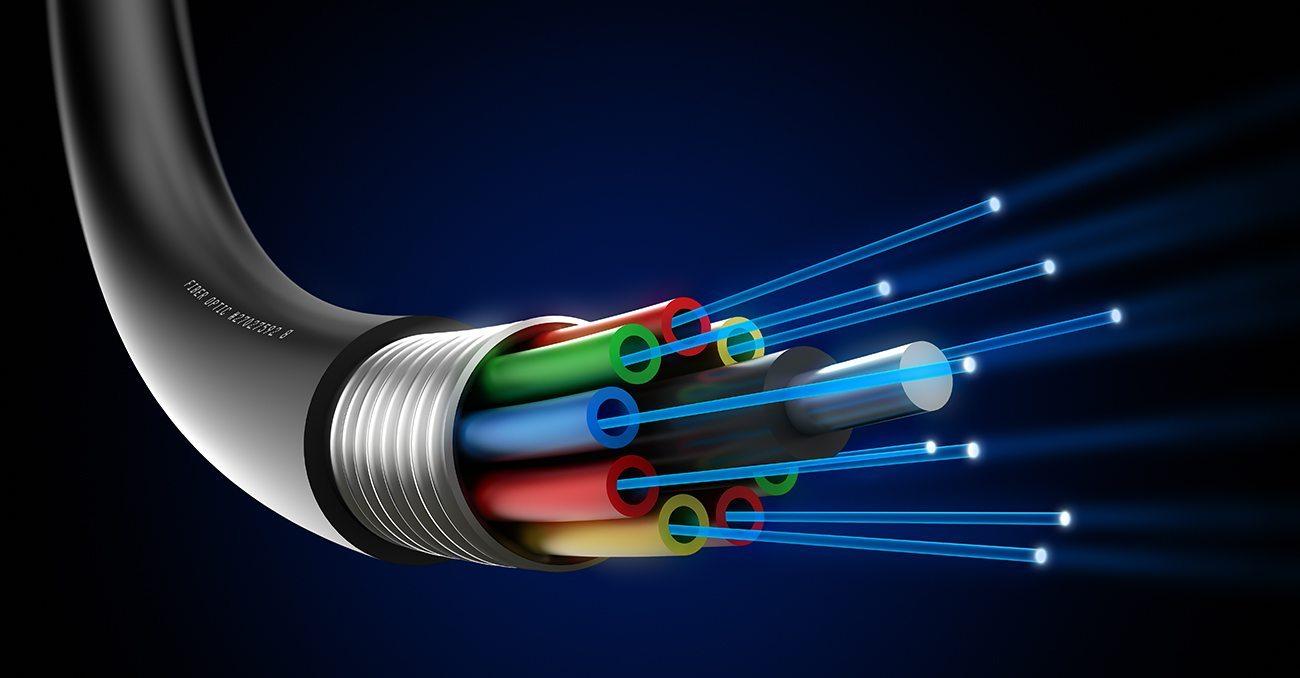

Horizontal directional drilling is a trenchless technique that is used to lay underground pipes and cables without breaking the road. This means that this technique can ensure that far fewer streets have to be broken up, so less inconvenience! But now… How does this work? When carrying out these horizontal drillings, good preparation is first required to ensure that the drilling does not suddenly cut straight through the fibre optic cable (or WIFI cable), as this would also cause inconvenience. Once the drilling has been prepared, good equipment and specialized drillers are needed to operate the machines.

This equipment includes a drilling machine to carry out the actual drilling. A mixing pump set to make a bentonite mixture. Pipe rollers, a generator, a recycler, and other equipment can also be part of this. I can hear you thinking; that are a lot of machines in the street. Will I still be able to reach my house?

Compact or mobile

Nowadays, machines can be built very compactly, which means the machine can deliver the same performance in a smaller size. As a result, only a small amount of space is required for the machine, which is practical when you need to drill in a narrow street. On the other hand, the majority of the machines can be built in a truck, a so-called drilling truck. This means you need space for the drilling truck and you need space to drive out the drilling machine that is in the truck. But… this also means that the machines are very easy to move, which makes it possible for a waste lorry to reach your house in the evening on the days when drillings take place in your street.

Bofram Techniek

Bofram Techniek is a custom machine builder. We engineer and realize various mix pump sets for both vertical and horizontal drilling. We think along in the process and our goal is to build a machine that meets our customer requirements but also provides a nice workplace for staff and as little inconvenience as possible for the environment. So if you have questions about HDD machines or HDD equipment that specific requirements/wishes, please contact us. Together we can look for a good solution for your project and who knows, together we can ensure that sustainable energy is facilitated with the preservation of the current streets and with less inconvenience for the residents of the Netherlands.