Construction of drilling truck and HDD mix pump unit

Bofram Techniek constructed a mud mixing truck for horizontal directional drilling. This page describes what happens in each phase of this project.

The construction process of the drilling truck

Phase 1 The wishes of the customer regarding the HDD equipment

Horizontal Directional Drilling (HDD) is the realization of horizontal drillings for the construction of pipes and tubes, without having to deconstruct the road. This requires professional equipment, such as a mud mixing truck with an HDD mix and pump set.

Our customer is active in this field and wanted a new built-in mix & pump unit that he can use with his Ditch Witch drill. After contacting us by phone, we sat down to discuss the details and needs to get a clear idea of their wishes.

Right after these conversations, the details were worked out by our engineers. They added some space-saving and noise-reducing possibilities. For example, the possibility to choose for a PTO driven hydraulic pump, so no extra engine is needed in the drilling vehicle. After some last detail adjustments and the agreement of both parties, we could start.

Phase 2 Preparation of the mud mixing truck and HDD mix pump unit

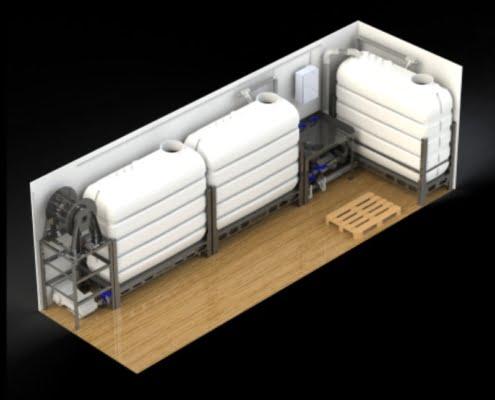

Preparation includes engineering, making the construction drawings, ordering the parts, and planning the various construction phases. The drawings are important to communicate to the whole team what the different parts look like, and how they exactly need to be assembled and/or placed. Furthermore, we have to make sure that the right specialists are working on the right part at the right time to make sure everything runs as smoothly as possible.

Phase 3 The complete construction of the drilling truck and HDD mix pump unit

When the MAN truck arrived, we started with the construction. First, we mounted the hydraulic drive system underneath the truck to save space. Afterward, we installed three water tanks. Why three? Our customer wanted one clean water tank, one mix tank, and one storage tank for the finished product. This way, the customer has both clean water and the finished product in stock at all times. Then, we built the frame of the bentonite hopper table and mounted the piping system. A hose reel is installed in the mud mixing vehicle as well.

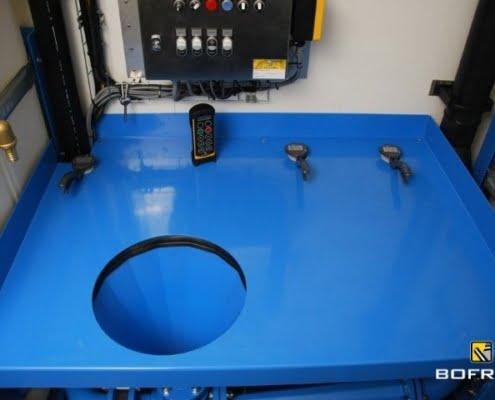

Phase 4 Powder coating of the construction parts in the drilling vehicle in the desired colors

When all the construction work has been custom-made to fit the mud mixing truck, it will be partially deconstructed again. The parts will be taken to the powder coater, where they are blasted completely clean. Then they are metalized, which minimizes oxidation. Finally, the parts are powder coated, so they get the desired color. In this case, blue is chosen as this is the customer’s company color. When the parts are ready, they are placed back in the drilling truck and the installation and assembly of the parts can continue. This is also the moment the pump is mounted in the drilling vehicle and the electro will be installed.

Phase 5 The test phase and last checks

When all components are mounted in the drilling vehicle, we enter the test phase. Within this phase, our specialists check if the HDD unit works properly and if small adjustments still need to be made. Because all our projects are unique, many constructions are different and so every test phase is unique. Bofram performs each test with great care so the customer encounters as few unforeseen situations as possible.

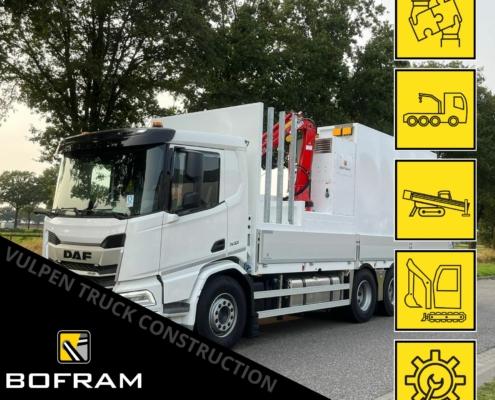

Phase 6 The delivery of the final product, ready for horizontal drilling

Once our specialists are completely satisfied with the performance of the HDD unit in the drilling truck, it is prepared for delivery. This means the customer can pick up the drilling vehicle or Bofram delivers the truck on location. When the drilling truck is delivered, Jos makes an appointment with the client to see how the HDD unit works in practice and to check if the customer is completely satisfied.

Bofram wishes the drill team of Dekabo a lot of safe horizontal drillings!

Specifications

- Mixing and high-pressure pumps can be used simultaneously.

- Tailor-made for a mud mixing truck in which the drill itself can be placed as well

- Hydraulic drive on truck PTO, fixed diesel engine speed

- Wireless remote control with Pressure reading and Liters per minute, low-level tank

- Turn on / off and set liters per minute of the high-pressure pump via the remote control

- Hydraulic-driven hose reel 50 meters with 1 1/4 ” high-pressure hose

- 3x 3000-liter tank for clean water, mixed product, and mix tank stock.

- Level measurement in the tank with low-level safety

- Use the high-pressure pump to clean the machine

- FMC high-pressure pump

- KSB mix pump with mechanical seal